KONSPEC manufactures a wide and extensive range of performance compounds based on Polyethylenes, Polypropylenes and Styrenics resins. These products are designed by carefully selecting active ingredients to suit end-use applications with respect to specific properties.

Performance materials are designed to meet the stringent requirements of advanced applications. This class of materials is meticulously engineered to exhibit outstanding mechanical, thermal, chemical, and electrical properties. To further optimize their performance and cater to specific applications, performance plastic compounds are utilized. These compounds consist of precisely blended mixtures of performance polymers, additives, fillers, and reinforcements to meet the exacting standards of specialized industries.

Performance plastics compounds epitomize a notable stride in material science, facilitating the creation of materials customized to cater to the precise requirements of high-performance sectors. These compounds offer a diverse array of attributes, such as heightened strength, heat resistance, chemical resilience, flame retardancy, and electrical properties. Their adaptability and personalized features render them indispensable in scenarios where conventional plastics prove inadequate in fulfilling the exacting standards of contemporary manufacturing and technology. As technology and industry progress, the role of performance plastics compounds becomes increasingly pivotal in expanding the horizons of possibilities across diverse domains.

Salient features

- Consistent batch to batch performance with respect to physical/mechanical properties

- Excellent processability

- Superior performance solution

- Best performance at least cost

- Optimized properties

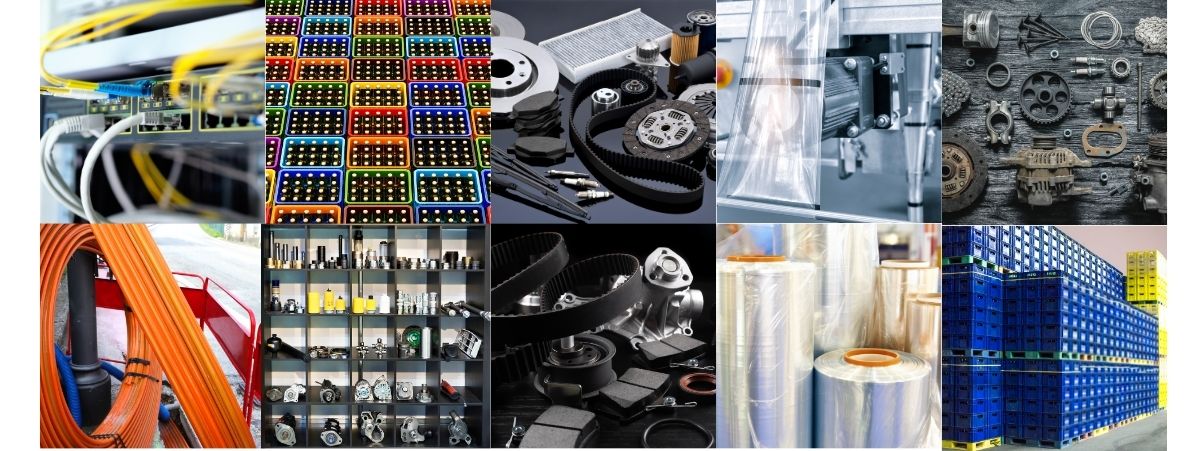

Product Range

- Mineral filled polymer compounds – Calcium filled/ Talc filled

- Flame Retardant compounds – Halogenated and Halogen Free

- Low Smoke Zero Halogen (LSZH) compounds

- Conductive compounds

- Silicone compounds for OFC (Optical Fibre Cable) ducts

- Breathable film compounds

MINERAL FILLED MATERIALS

Mineral filled Materials are offered to improves Mechanical and stiffness of the Polymers. Calcium carbonate and Talc are two common inorganic fillers that are frequently used in polymer composites to enhance their mechanical, thermal, and functional properties. These fillers have different properties and characteristics that make them suitable for various applications.

Calcium carbonate and talc filled polymers are two popular choices for enhancing the properties of polymer composites. While they share some similarities, they also have distinct differences in terms of their properties, applications. Understanding the benefits of each filler is essential for selecting the right material for a particular application. By optimizing the filler content, surface modification, and polymer matrix composition, it’s possible to create high-performance polymer composites with improved mechanical, thermal, and functional properties.

FLAMER RETARDANT COMPOUNDS

Flame retardant compounds and masterbatches are materials that are added to plastics to reduce their flammability and slow down the spread of fire. These materials are commonly used in industries such as aerospace, automotive, construction, and electronics, where products are subjected to high temperatures or are located in close proximity to potential ignition sources.

Flame retardant compounds are typically made up of a combination of chemicals that work together to prevent the propagation of fire. These compounds can be either brominated or Non-Halogen Based.The selection of a flame-retardant compound or masterbatch depends on various factors, including the type of polymer being processed, the intended application, and the desired level of flame retardancy. Flame retardant compounds and masterbatches must meet strict regulatory requirements and undergo rigorous testing to ensure their efficacy and safety. Common tests include the UL 94 test, which measures the flame retardancy of plastic materials

LOW SMOKE ZERO HALOGEN

LSZH materials are designed to produce minimal smoke and no harmful halogenated gases when exposed to high temperatures, making them ideal for use in enclosed spaces like cable ducts. Here are some examples of LSZH compounds that can be used for optical fiber cable ducts:

FR COMPOUNDS FOR PP CONTAINERS

Flame retardant PP containers for railways are designed to meet the strict safety standards required for the transportation of goods by rail. These containers are made from a special type of polypropylene (PP) that has been treated with flame retardants to reduce its flammability and slow down the spread of fire in case of an accident.The use of flame-retardant PP containers in railways is becoming increasingly popular due to their many benefits, which include Improved safety: The most obvious benefit of using flame retardant PP containers is the improved safety they offer. In the event of a fire, these containers can help to slow down the spread of the blaze, giving people time to evacuate the area and emergency services time to respond.

CONDUCTIVE COMPOUND FOR CRATES

Conductive crates are commonly used in the electronic industry for various purposes, including:

Protection of sensitive electronic components: Conductive crates provide a shielded environment that protects sensitive electronic components from external electromagnetic interference (EMI) and radio-frequency interference (RFI). This helps to ensure the reliable performance and longevity of the components.

Conductive crates can be grounded, which allows them to dissipate any accumulated static electricity and prevent damage to electronic components. This is particularly important in dry environments where static electricity can build up easily.

CONDUCTIVE COMPOUNDS FOR CORRUGATED SHEETS

Corrugated sheets are widely used in various industries for packaging, construction, and other purposes. However, conventional corrugated sheets are made from paper or cardboard, which can be fragile and prone to damage. To address this issue, conductive PP corrugated sheets have been developed, offering a durable and versatile alternative. In this note, we will explore the features, benefits, and potential applications of conductive PP corrugated sheets.

Conductive PP corrugated sheets are made from polypropylene (PP), a thermoplastic material known for its excellent strength, durability, and resistance to heat, moisture, and chemicals. The addition of conductive particles enables the sheet to dissipate static electricity, making it an ideal choice for applications where electrostatic discharge (ESD) protection is required.

Applications

- Injection moulded components

- Automotive components

- Automotive batteries

- Material handling crates for electronic industries

- Optical fibre ducts/ corrugated ducts

- Breathable/Hygiene films

- Many more